Machine Nozzles Fundamentals Explained

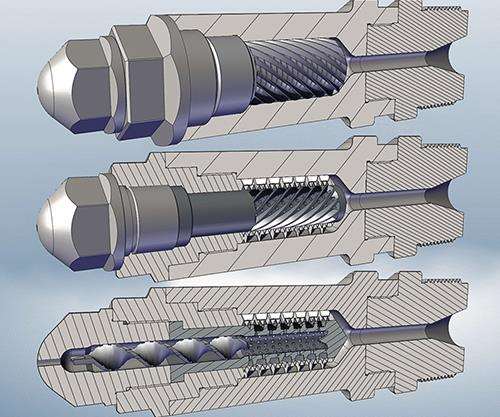

The outer size is precisely machined to permit it to glide right into the bore of the inner size of the maker nozzle body with very little clearance. Along the external diameter of the gap filter, an even number of networks is machined, developing several parallel, lengthwise melt-flow networks along the external diameter of the void filter.

The thin walls of steel are the side walls of the circulation networks. When the space filter is moved right into the birthed of the inner size of the equipment nozzle, the internal diameter of the nozzle produces a lid in addition to the machined groove, completely enclosing the melt-flow channels.

On one side of the filter, openings are after that pierced into every various other machined groove, to allow the thaw to stream right into every other melt-channel groove from the shot barrel side of the nozzle. On the mold and mildew side of the cylinder, openings are pierced right into the alternating melt-channel grooves, which allow melt to move out of every other machined groove as well as right into the mold.

The melt trips throughout of the machined-groove thaw networks where they are then entraped within the gap filter with no method to access the machined groove thaw networks that exit the filter right into the mold and mildew. The walls or slim ribs of steel on either end of the machined grooves are machined down somewhat. machine nozzles.

These spaces enable melt to roll over the thin wall surfaces that divide adjacent machined groove melt channels. Hence the thaw might continue to pass through from one grooved flow network right into surrounding grooved channels by flowing over the tops of the ribs. The dimension of the machined spaces determines just how conveniently the melt can stream from one thaw network to an adjacent circulation channel as well as likewise establishes the size of particle or contaminant that will certainly be caught in the gaps between the tops of the ribs and the internal size of the maker nozzle.

Another advantage of this style is that as impurity is caught, it connects a much smaller sized percentage of the circulation channel. Hence, significantly more pollutant might be recorded in a void filter prior to any type of noticeable rise in stress decline occurs. With a void filter, it is quite usual that even after competing a long time as well as catching a fair amount of contaminant, the space filter might still have a lower pressure decline than a tidy display pack.

Fascination About Machine Nozzles

A last note on the void filter nozzle is that there is a design readily available that permits purging of the impurity without having to remove the filter from the nozzle. With the purgeable nozzle filter, pollutant can be removed without having to dismantle the nozzle. This design provides for minimal downtime during cleansing, as the nozzle filter might be removed within a few minutes between shots, supplying optimum uptime on the handling flooring.

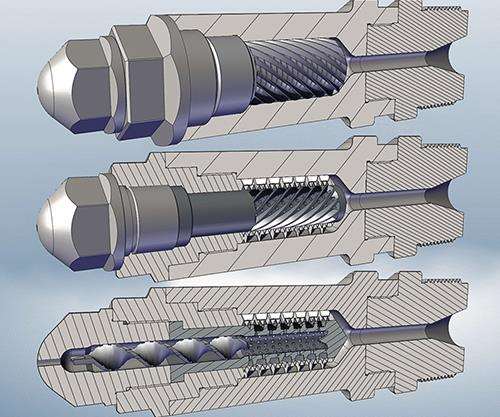

Blending nozzles likewise aid ensure a much more consistent and uniform thaw overall, consisting of temperature level dispersion. Some Mixing nozzles use modifications in flow-channel volumes to produce alternating locations of higher and reduced pressure as the melt trips with the nozzle. Some mixing nozzles might present unacceptable degrees of shear or anxiety to the thaw.

The "triple-action" mixing nozzle folds up the thaw onto itself, ensuring gentle yet through mixing of the melt. As the thaw goes into the nozzle it is routed to the outer diameter, where clockwise spiral strings start revolving the thaw. Slotted openings on the inner diameter of the spiral flow channel then relocate the material internal right into a 2nd set of counterclockwise spiral circulation networks, folding the polycarbonate thaw onto itself once more as it starts revolving in the opposite direction.

This triple-action mixing makes sure a gentle yet thorough blending of the melt. The ports and also small-diameter openings that the thaw go through as it proceeds internal along the nozzle give the added benefit of filtering the material as it proceeds via the nozzle. The dimension of the filter can be customized to the molder's specs.

A simple remedy for molders doing regular shade modifications while utilizing the triple-action blending nozzle is to have two blending nozzles available. When transforming colors, the molder just swaps nozzles. The blending nozzle that was pulled from the equipment might then be cleaned up and prepped for the next color change.

The dimension of filtration and also gentle mixing action of the triple-action nozzle lessen the pressure drop as well as quantity of shear that the thaw sees as it goes across through the nozzle. That makes the triple-action blending nozzle an excellent prospect for applications using shear-sensitive thermoplastics, consisting of PET, with color concentrate and/or other additives.

Some Known Factual Statements About Machine Nozzles

It is desirableto minimize the drool from the nozzle in such applications. There are a wide range of layouts to shut down the thaw, consisting of shut-off pins or needles, ball-valve shut-offs, blade shut-offs, and so on. There are additionally a selection of techniques for activating the shut-off, including hydraulics, pneumatics, or springs.

To simplify the procedure as well as reduce the potential for error, which in some cases can bring about disastrous failing, the shut-off procedure needs to happen instantly in the majority of applications. machine nozzles. It is additionally desirable that the shut-off nozzle include an integrated safety and security attribute to make sure that the nozzle is not over-pressurized in situations where journalism is still with heats up on for an extended duration.

Once the injection pressure gets to a fixed degree, the spring is pressed, enabling the thaw to flow past the needle shutoff, which is held open as long as the injection pressure stays over the predetermined degree. As quickly as the injection stress goes down below that degree, the springtime moves the needle shutoff onward right into the shut position, immediately closing off the melt circulation.

Learn More go to this web-site click to find out more